OPERATIONALIZING A GLOBAL CIRCULAR IT HARDWARE INDUSTRY E R I K R I E D E L , S V P, E N G I N E E R I N G IFX Las Vegas December 2019 @ITRenewInc

A presentation at IFX 2019 - Celebrating the Craft & Culture of Infrastructure in December 2019 in Las Vegas, NV, USA by erik riedel

OPERATIONALIZING A GLOBAL CIRCULAR IT HARDWARE INDUSTRY E R I K R I E D E L , S V P, E N G I N E E R I N G IFX Las Vegas December 2019 @ITRenewInc

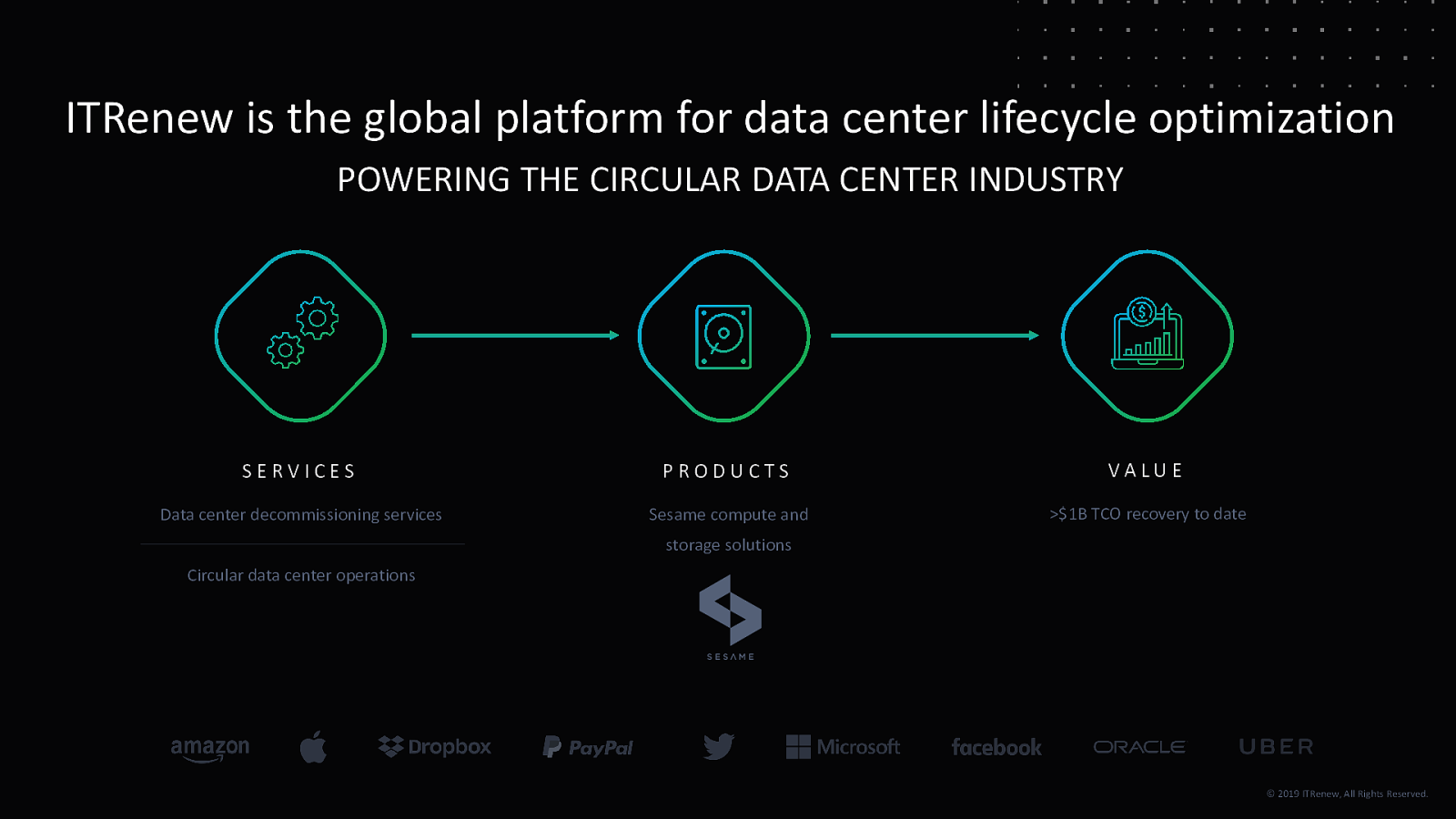

ITRenew is the global platform for data center lifecycle optimization POWERING THE CIRCULAR DATA CENTER INDUSTRY SERVICES PRODUCTS VALUE Data center decommissioning services Sesame compute and

$1B TCO recovery to date storage solutions Circular data center operations © 2019 ITRenew, All Rights Reserved.

© 2019 ITRenew, All Rights Reserved.

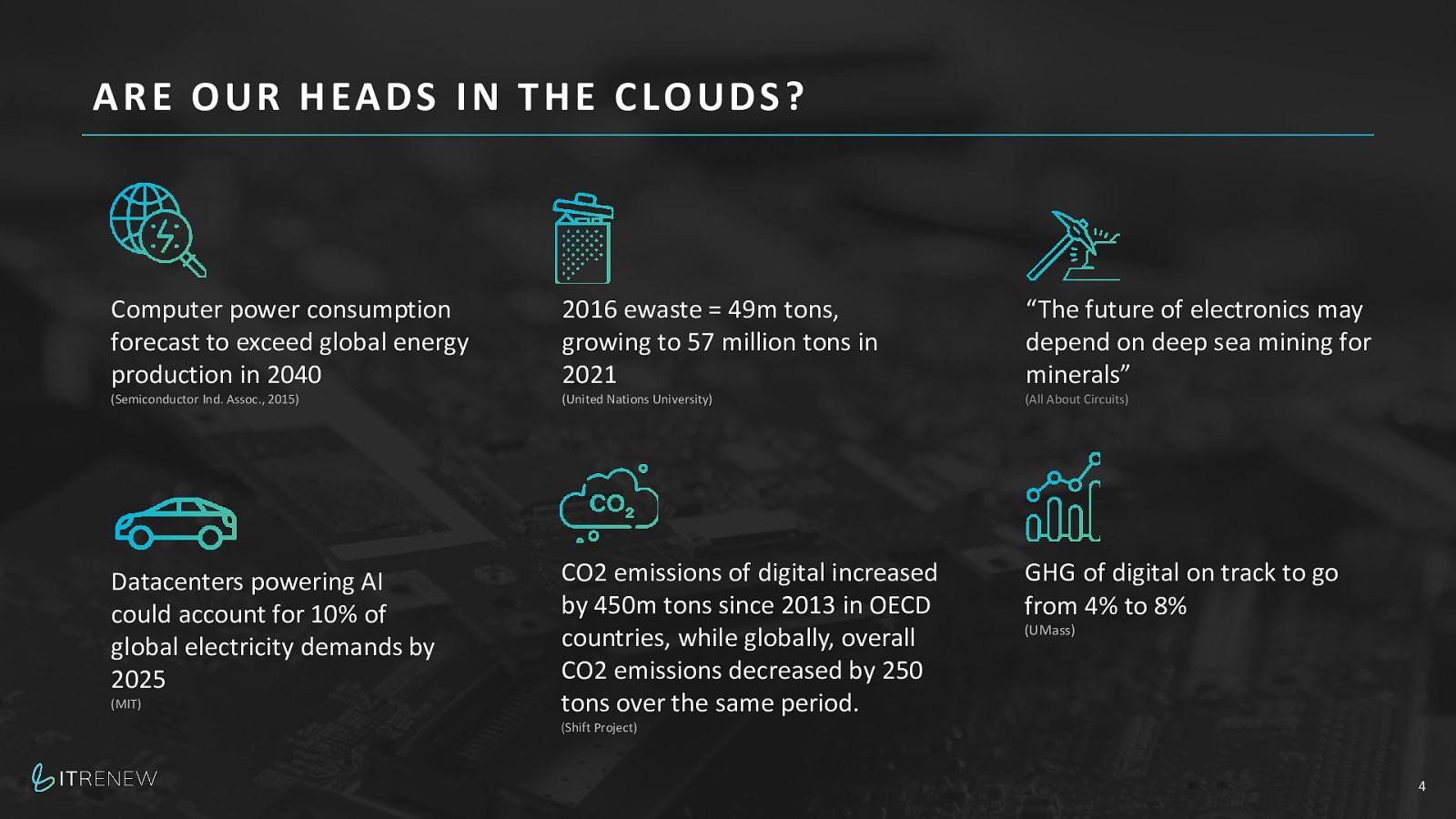

A R E O U R H EA D S I N T H E C LO U D S ? Computer power consumption forecast to exceed global energy production in 2040 2016 ewaste = 49m tons, growing to 57 million tons in 2021 “The future of electronics may depend on deep sea mining for minerals” Datacenters powering AI could account for 10% of global electricity demands by 2025 CO2 emissions of digital increased by 450m tons since 2013 in OECD countries, while globally, overall CO2 emissions decreased by 250 tons over the same period. GHG of digital on track to go from 4% to 8% (Semiconductor Ind. Assoc., 2015) (MIT) (United Nations University) (All About Circuits) (UMass) (Shift Project) 4

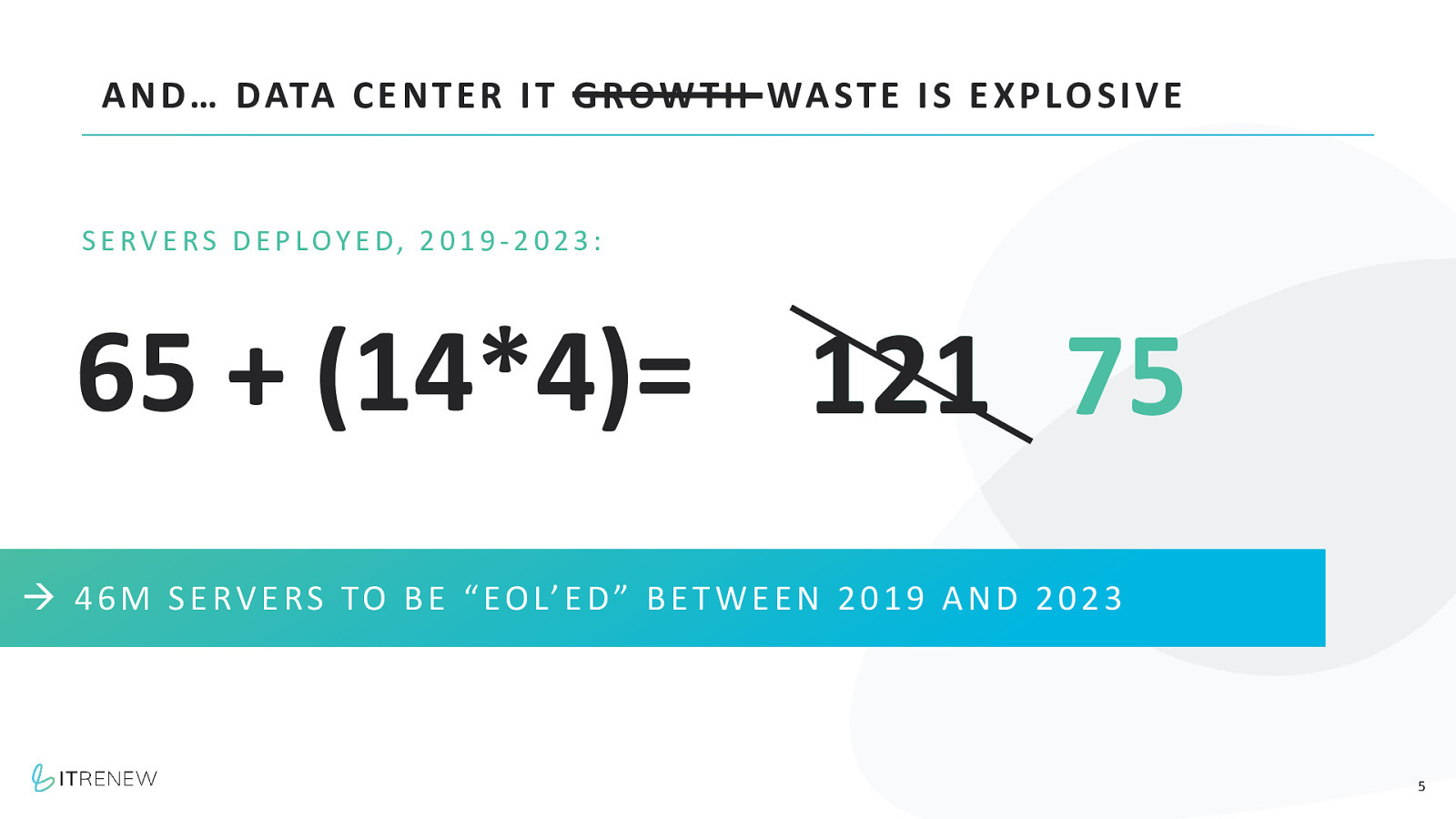

A N D … DATA C E N T E R I T G R O W T H WA S T E I S E X P LO S I V E SERVERS DEPLOYED, 2019-2023: 65 + (14*4)= 121 75 4 6 M S E R V E R S TO B E “ E O L’ E D ” B E T W E E N 2 0 1 9 A N D 2 0 2 3 5

W H AT W E A R E D O I N G R EA L LY W E L L • • • • • PUE waste reduction Computational efficiency Utilization and power scaling Cooling, power efficiency Renewables 6

R E N E WA B L E P RO G R ES S 7

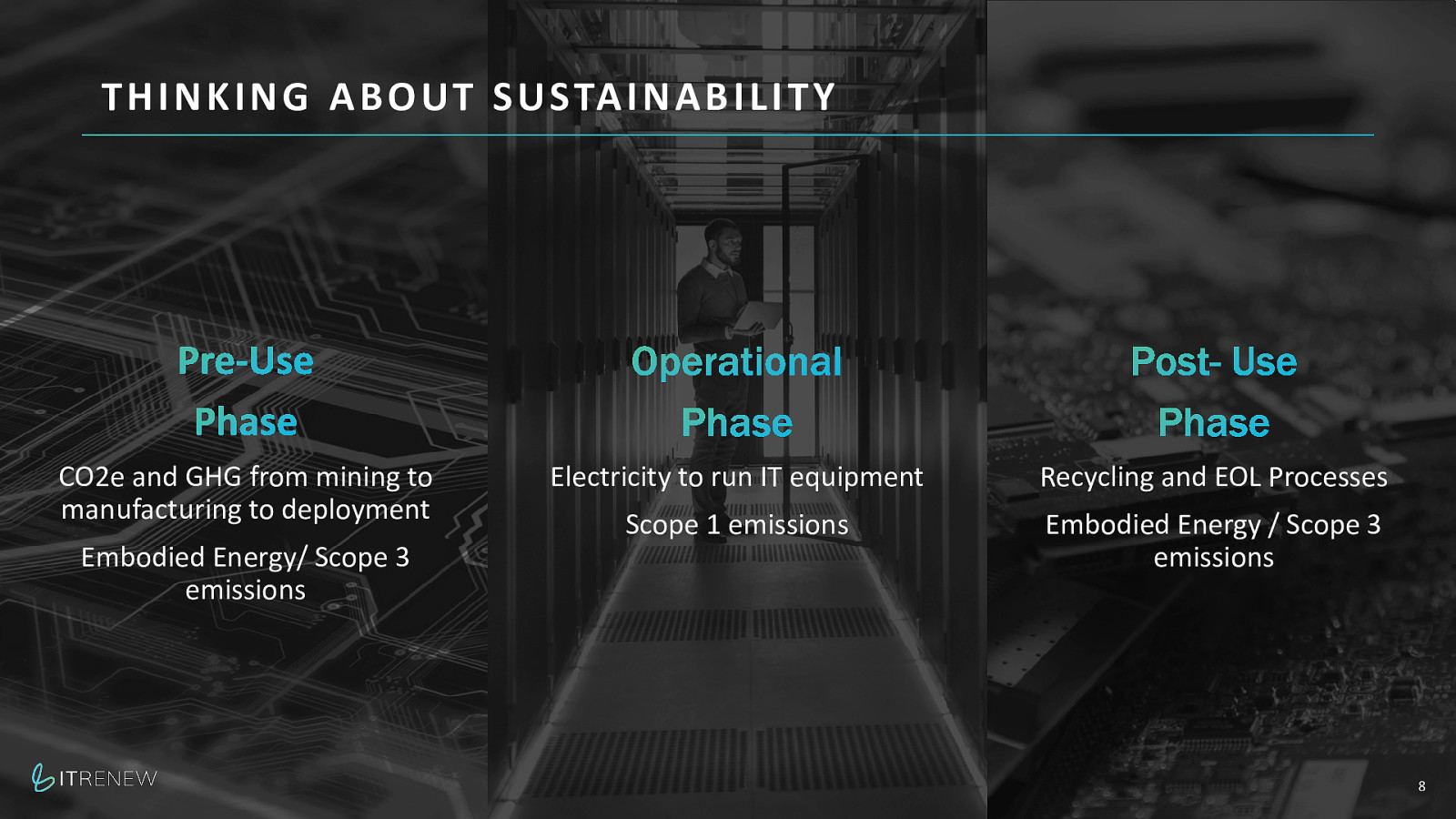

T H I N K I N G A B O U T S U STA I N A B I L I T Y CO2e and GHG from mining to manufacturing to deployment Embodied Energy/ Scope 3 emissions Electricity to run IT equipment Recycling and EOL Processes Scope 1 emissions Embodied Energy / Scope 3 emissions 8

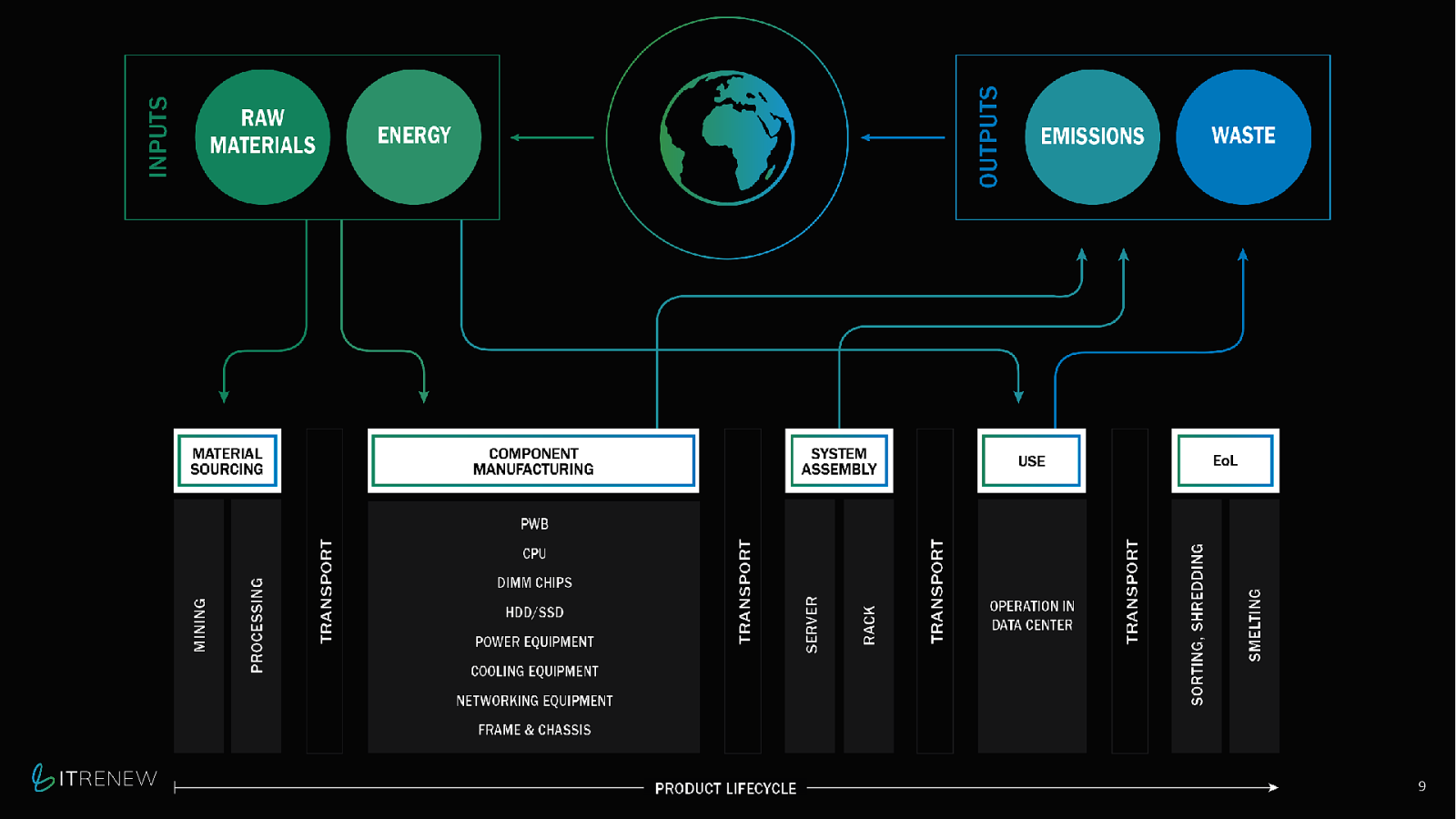

9

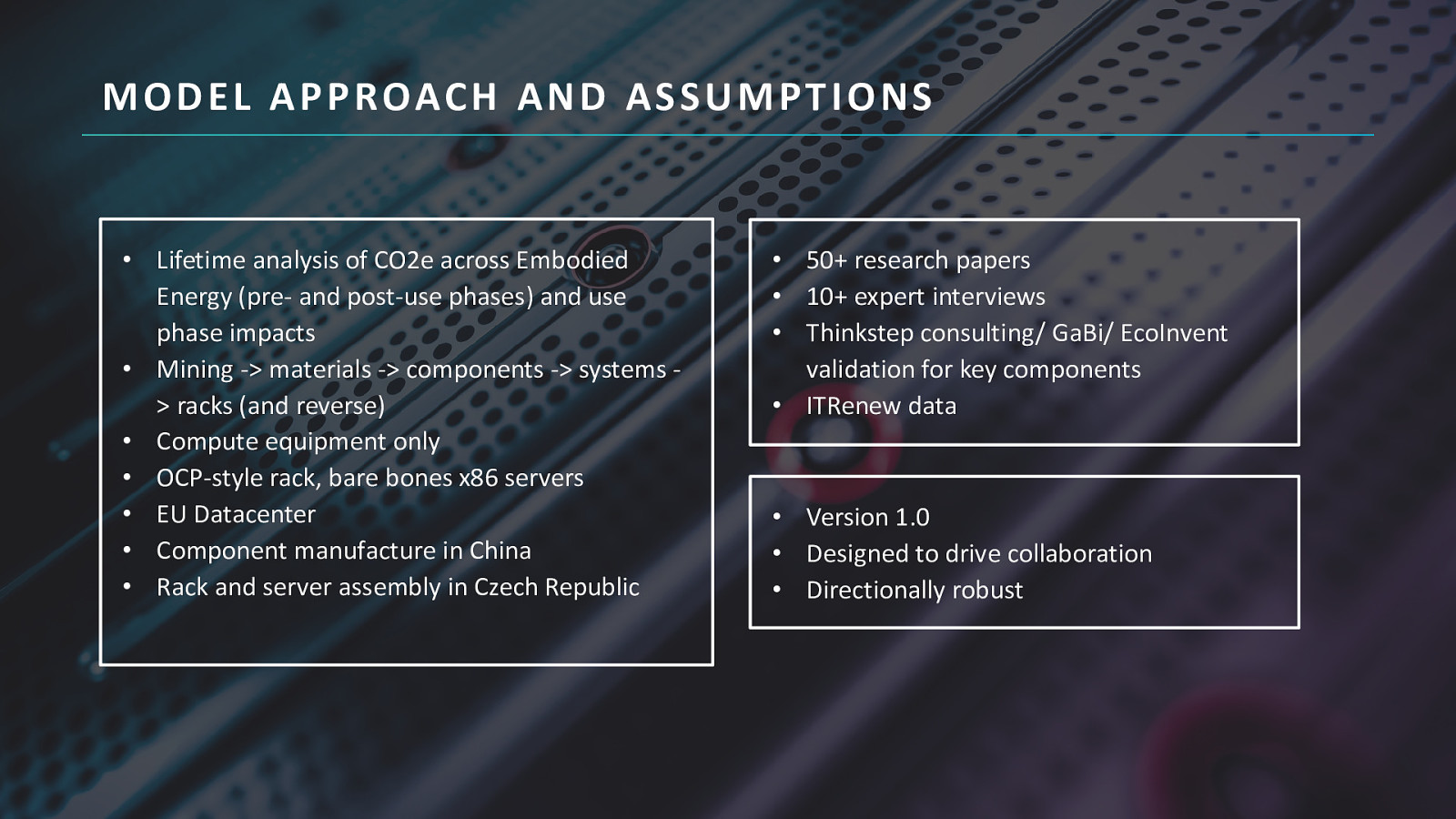

M O D E L A P P ROAC H A N D A S S U M P T I O N S • Lifetime analysis of CO2e across Embodied Energy (pre- and post-use phases) and use phase impacts • Mining -> materials -> components -> systems > racks (and reverse) • Compute equipment only • OCP-style rack, bare bones x86 servers • EU Datacenter • Component manufacture in China • Rack and server assembly in Czech Republic • 50+ research papers • 10+ expert interviews • Thinkstep consulting/ GaBi/ EcoInvent validation for key components • ITRenew data • Version 1.0 • Designed to drive collaboration • Directionally robust 10

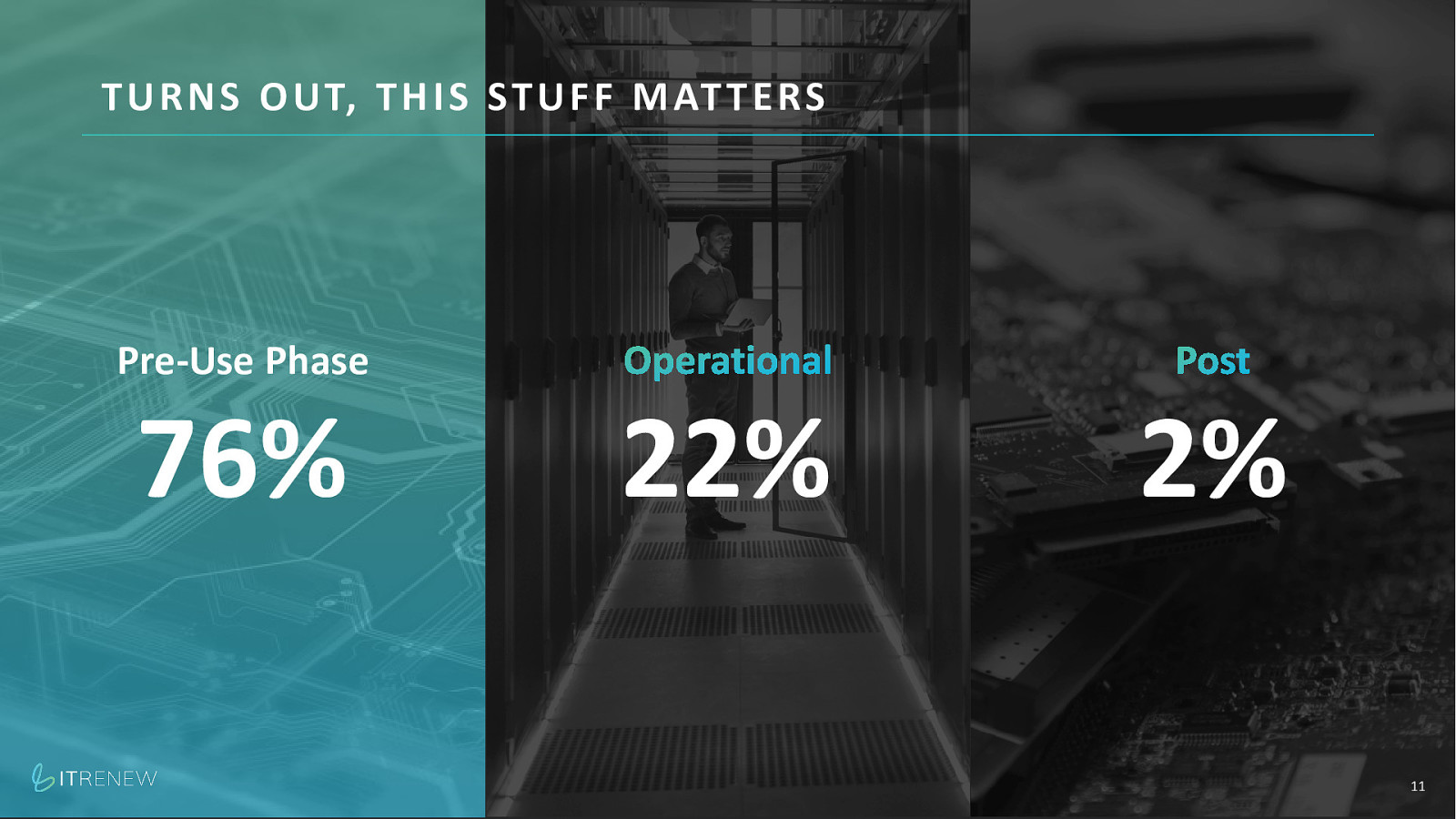

T U R N S O U T, T H I S ST U F F M AT T E RS Pre-Use Phase 76% 22% 2% 11

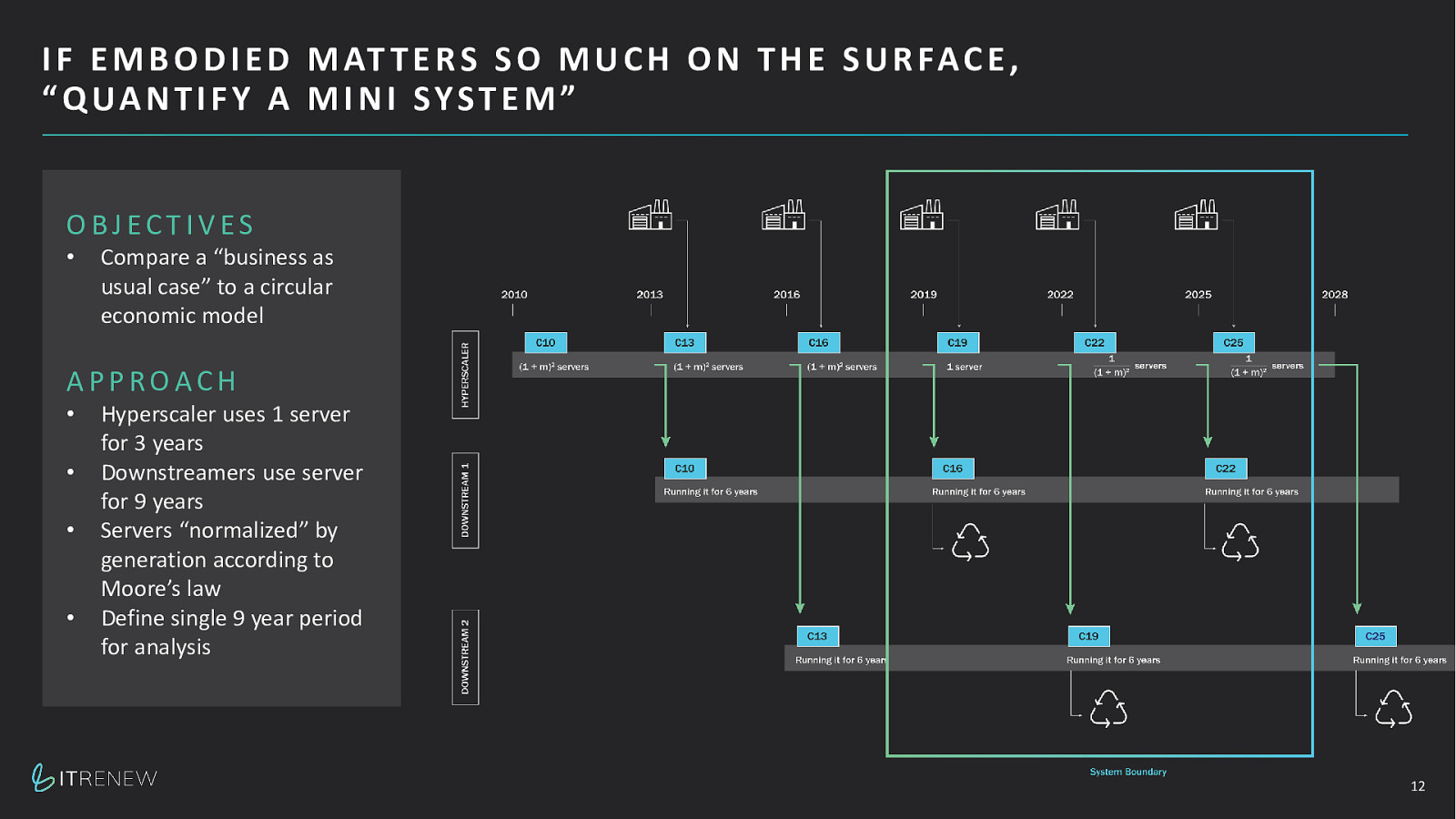

I F E M B O D I E D M AT T E R S S O M U C H O N T H E S U R FA C E , “QUANTIFY A MINI SYSTEM” OBJECTIVES • Compare a “business as usual case” to a circular economic model APPROACH • • • • Hyperscaler uses 1 server for 3 years Downstreamers use server for 9 years Servers “normalized” by generation according to Moore’s law Define single 9 year period for analysis 12

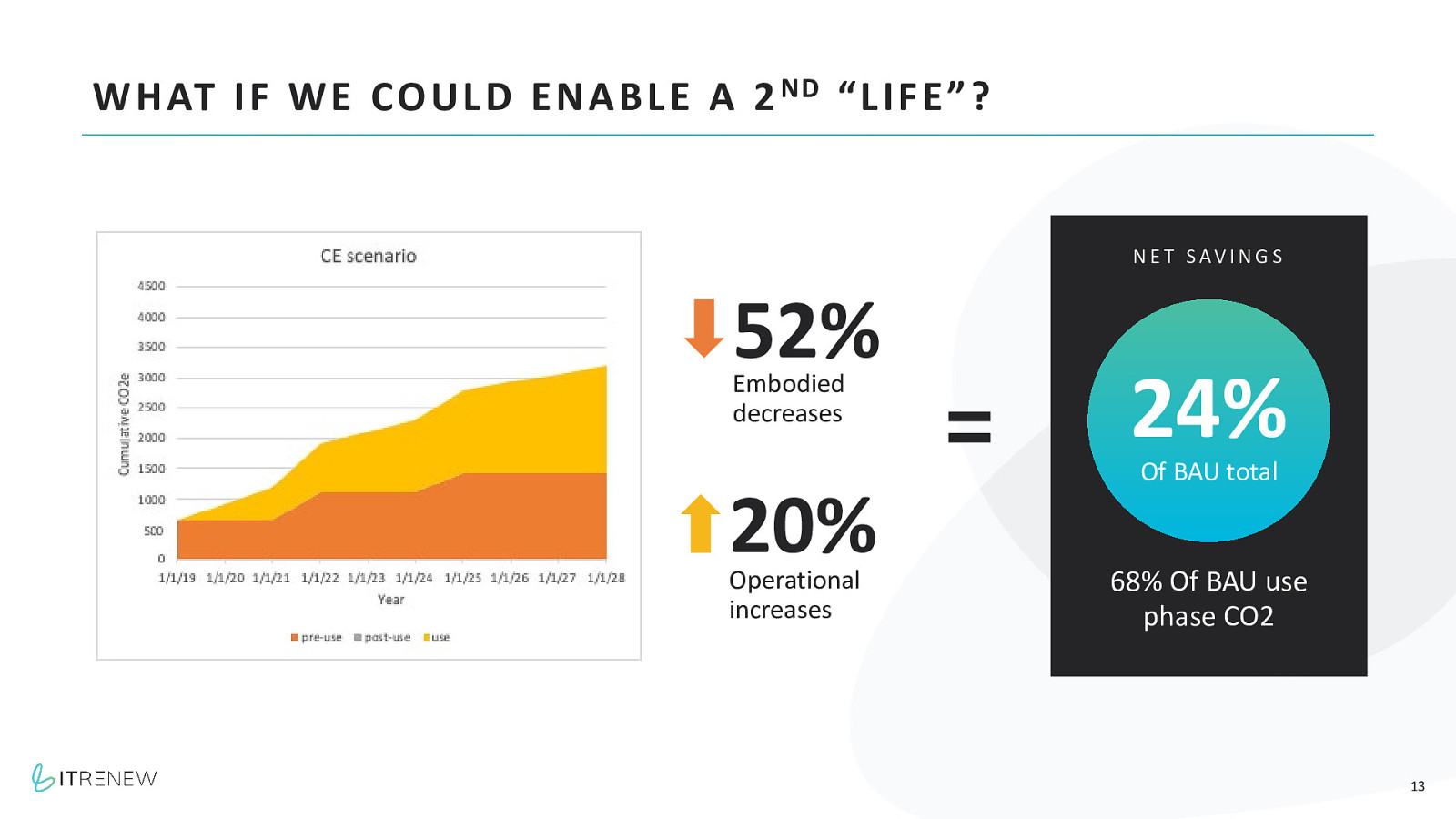

24% Of BAU total 68% Of BAU use phase CO2 13

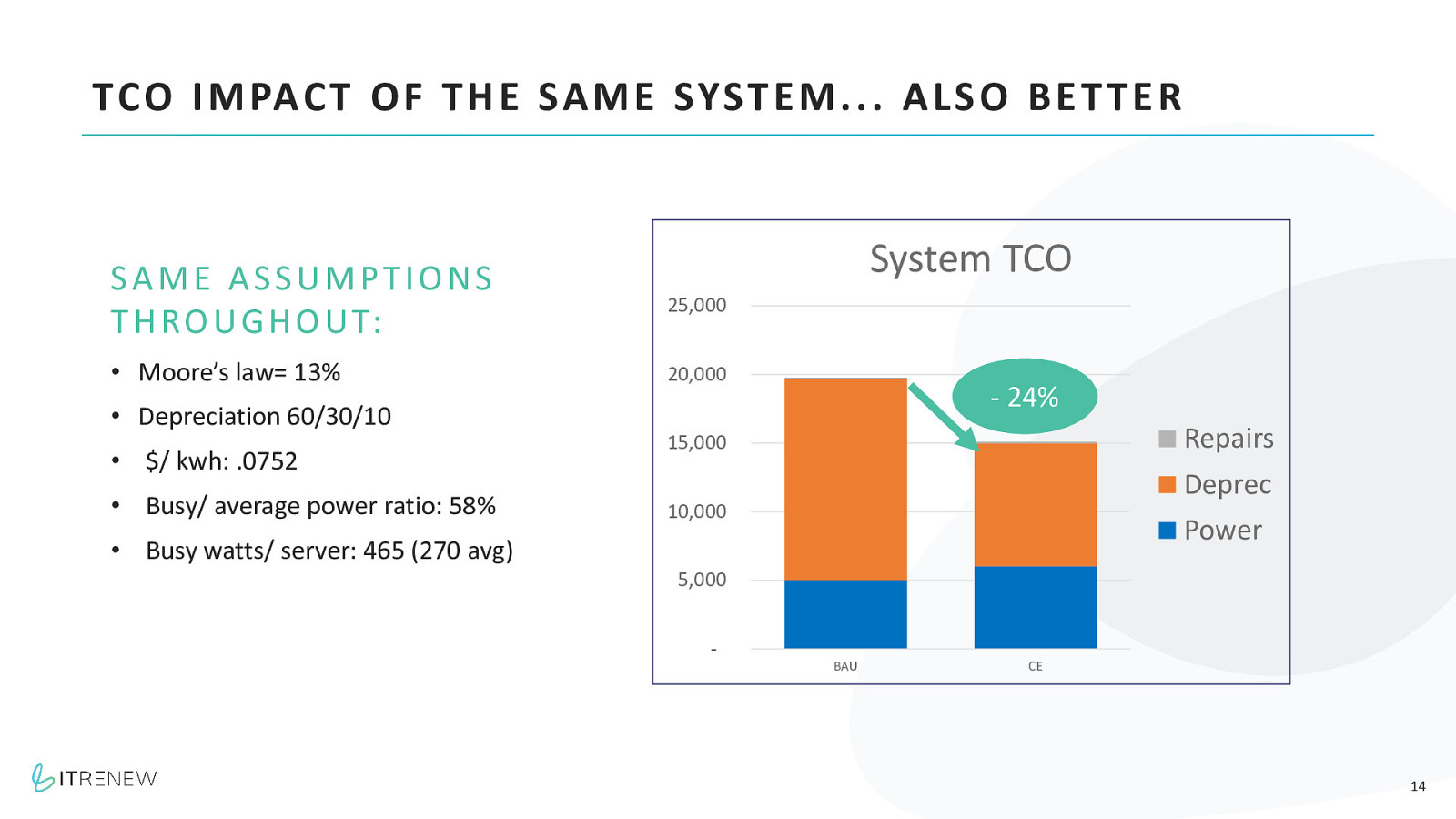

TCO I M PAC T O F T H E SA M E SYST E M … A L S O B E T T E R System TCO SAME ASSUMPTIONS T H R O U G H O U T: 25,000 • Moore’s law= 13% 20,000 • Depreciation 60/30/10 • $/ kwh: .0752 • Busy/ average power ratio: 58% • Busy watts/ server: 465 (270 avg)

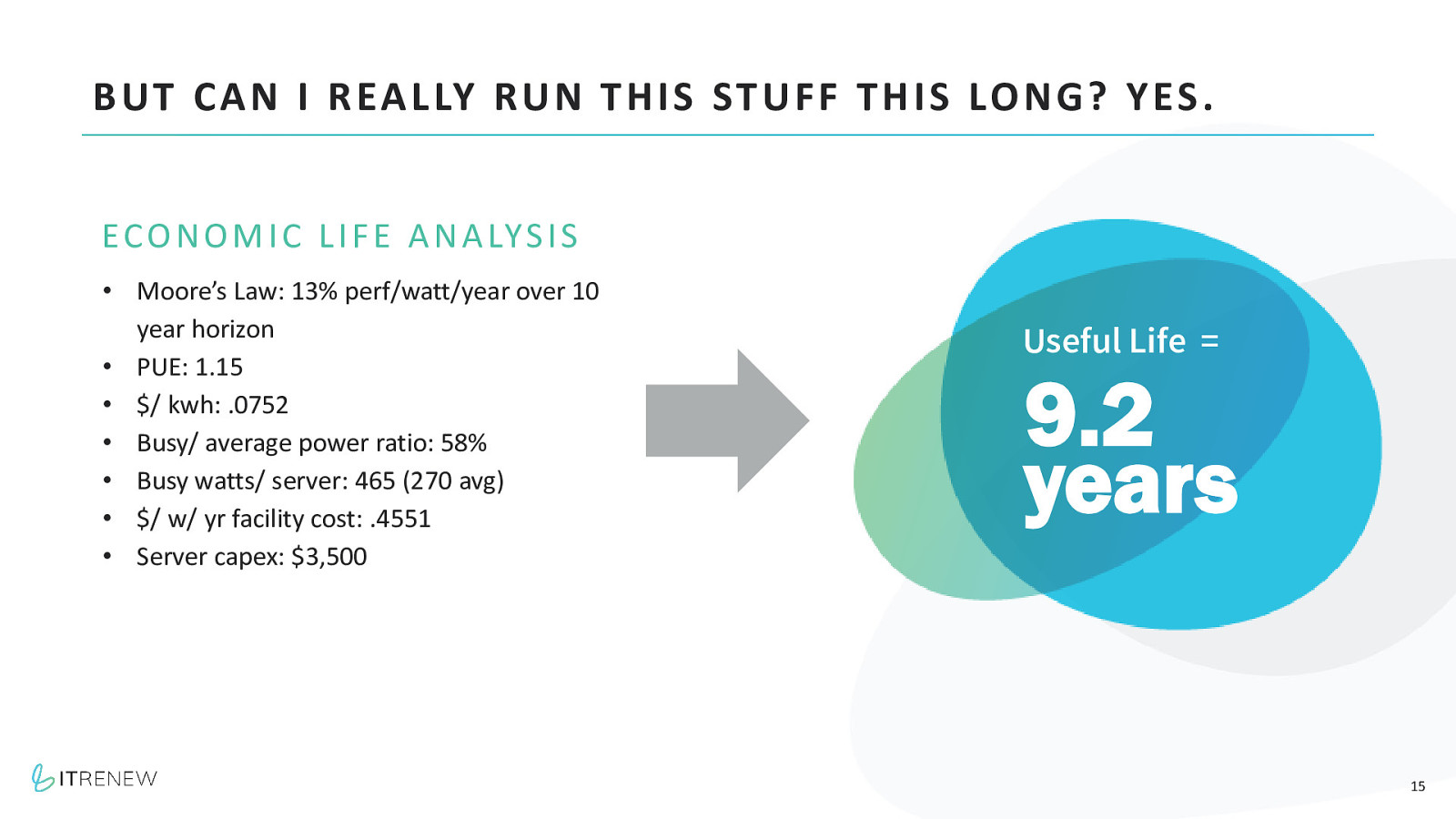

B U T C A N I R EA L LY R U N T H I S ST U F F T H I S LO N G ? Y ES . E C O N O M I C L I F E A N A LY S I S • Moore’s Law: 13% perf/watt/year over 10 year horizon • PUE: 1.15 • $/ kwh: .0752 • Busy/ average power ratio: 58% • Busy watts/ server: 465 (270 avg) • $/ w/ yr facility cost: .4551 • Server capex: $3,500 Useful Life = 9.2 years 15

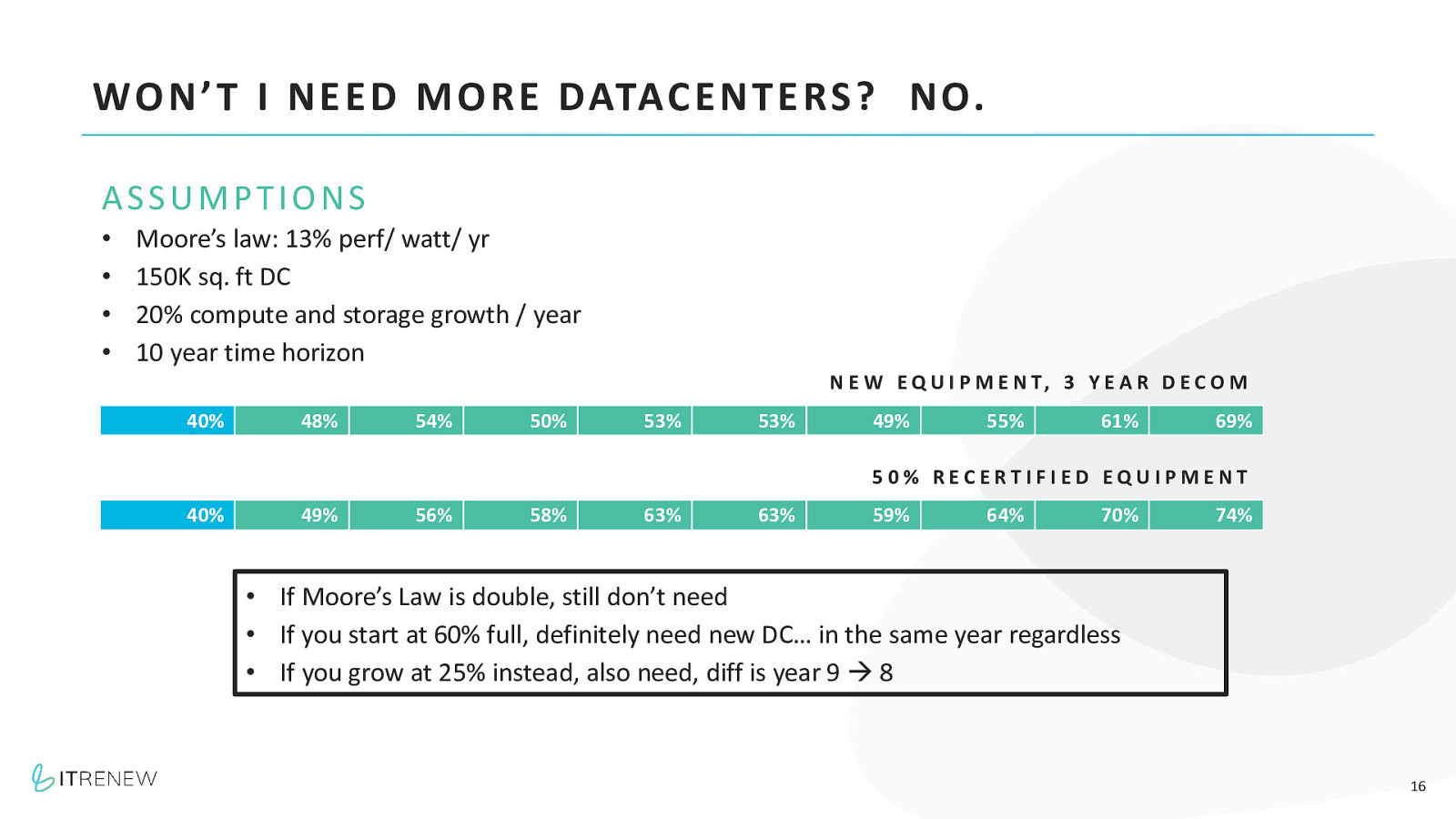

WO N ’ T I N E E D M O R E DATAC E N T E RS ? N O. ASSUMPTIONS • • • • Moore’s law: 13% perf/ watt/ yr 150K sq. ft DC 20% compute and storage growth / year 10 year time horizon 40% 48% 54% 50% N E W E Q U I P M E N T, 3 Y E A R D E C O M 53% 53% 49% 55% 61% 69% 50% RECERTIFIED EQUIPMENT 40% 49% 56% 58% 63% 63% 59% 64% 70% 74% • If Moore’s Law is double, still don’t need • If you start at 60% full, definitely need new DC… in the same year regardless • If you grow at 25% instead, also need, diff is year 9 8 16

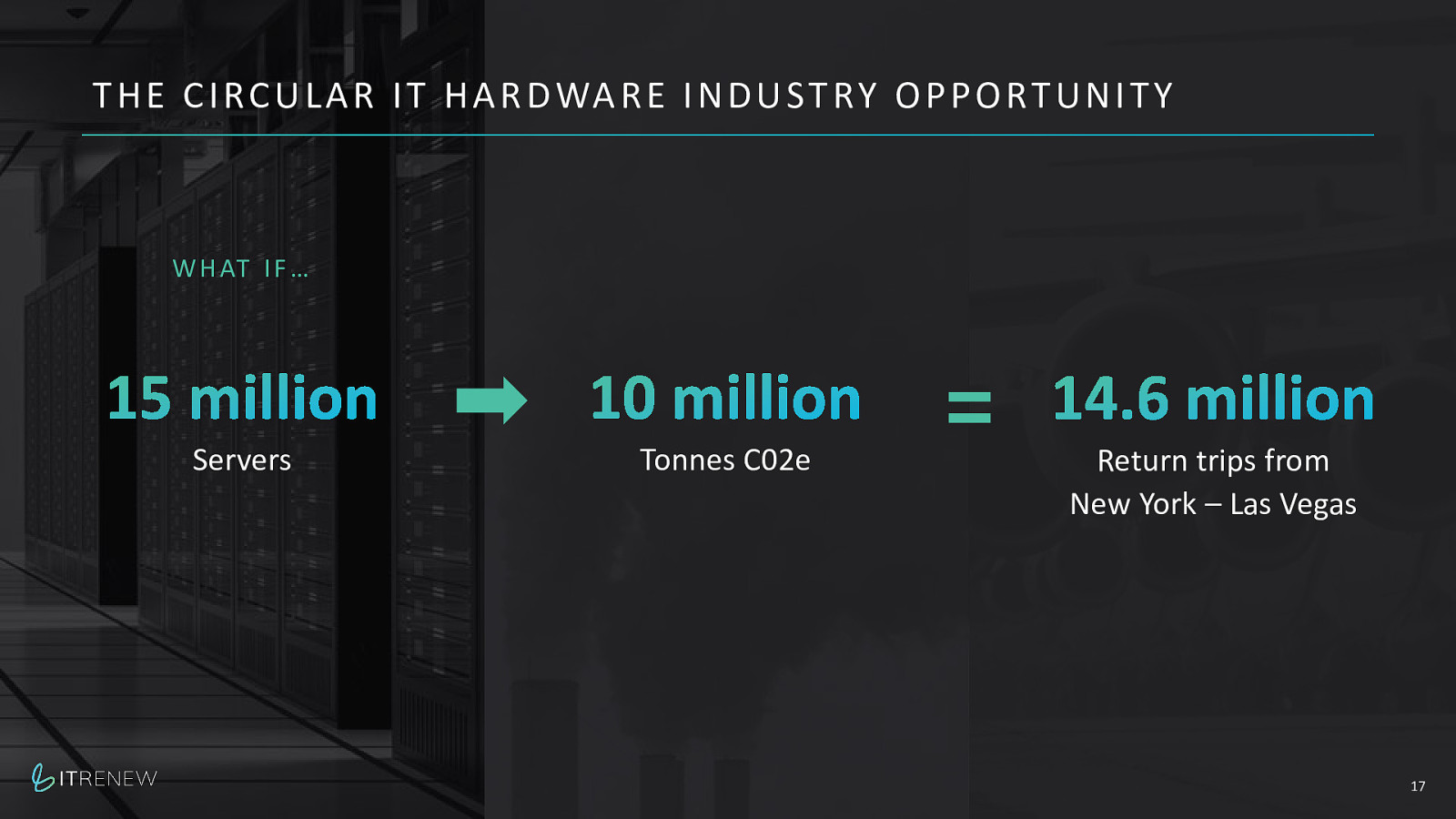

Return trips from New York – Las Vegas 17

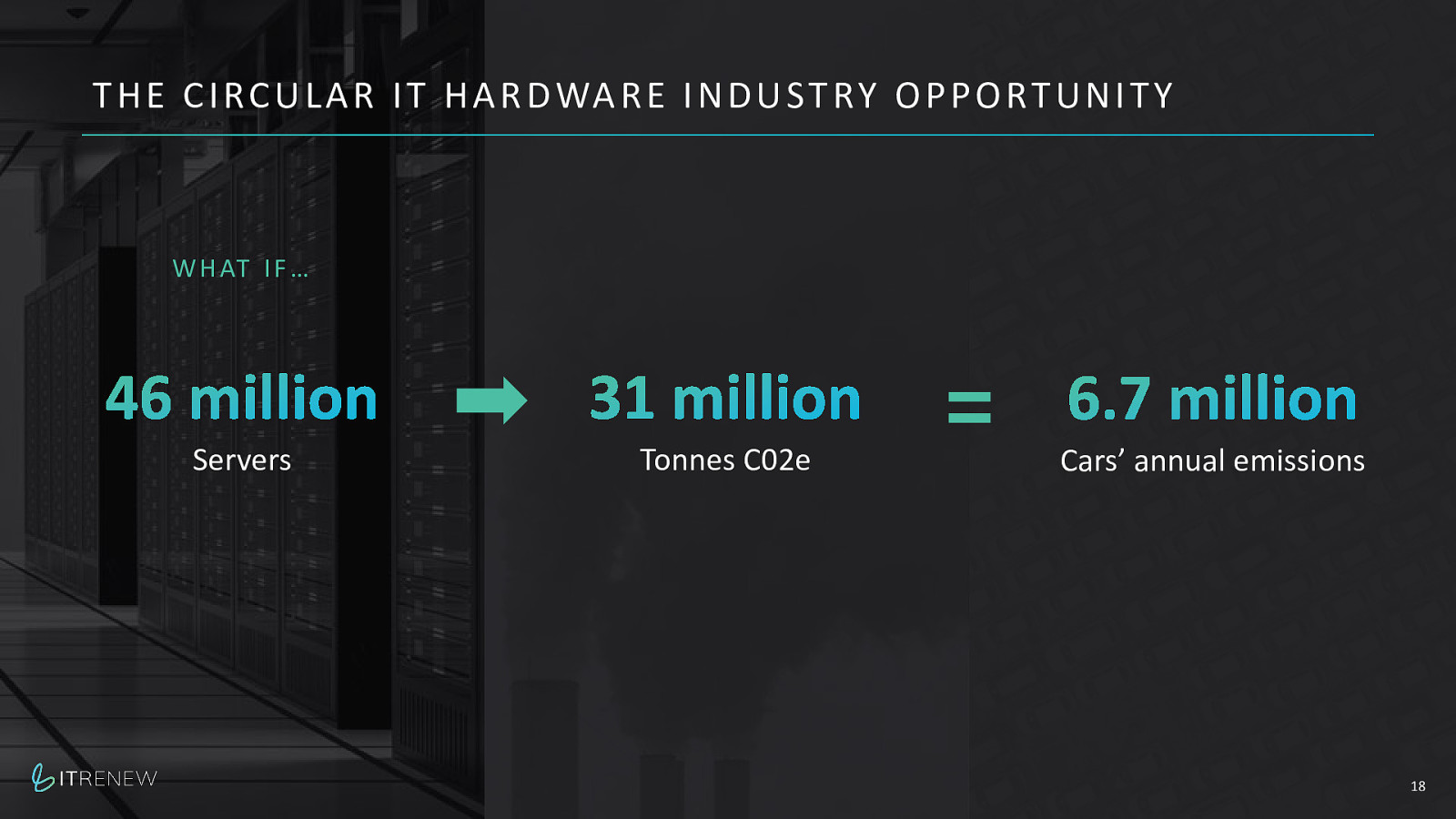

Cars’ annual emissions 18

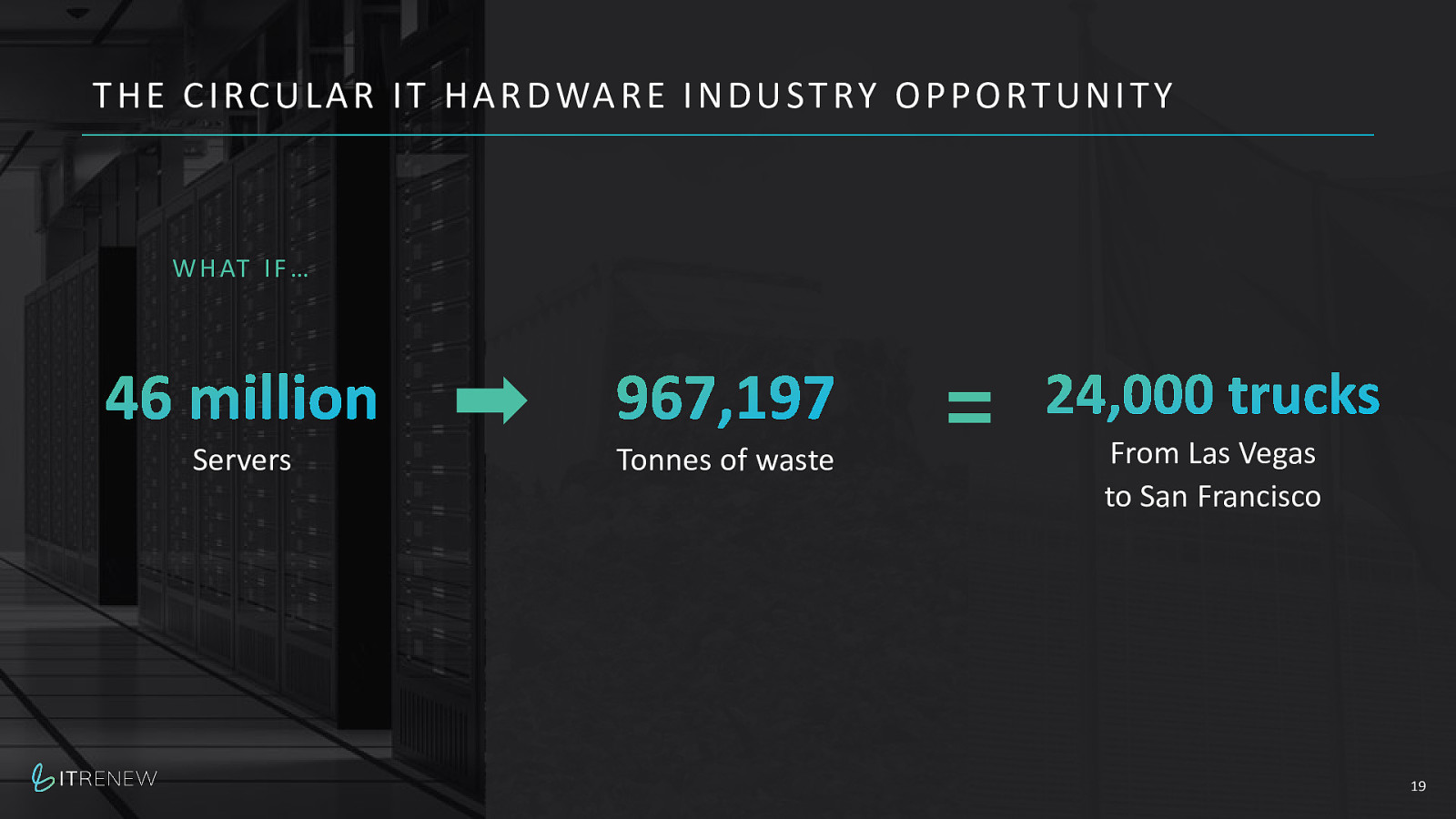

From Las Vegas to San Francisco 19

WHAT DOES THIS LOOK LIKE IN ACTION? 20

O P E N I S E S S E N T I A L , B U T N OT S U F F I C I E N T Open source software stack to enable support Design, engineering and product expertise, rigorous commitment to quality Market-making scale and diversity of downstream channels SERVICES AND PRODUCTS + a changed mindset and shared ethos ORCHESTRATING across the ecosystem A GLOBAL CIRCULAR IT HARDWARE INDUSTRY Global operations and logistics footprint – time to market is critical Automation and machine learning to fuel both customization and efficiency at hyperscale 21

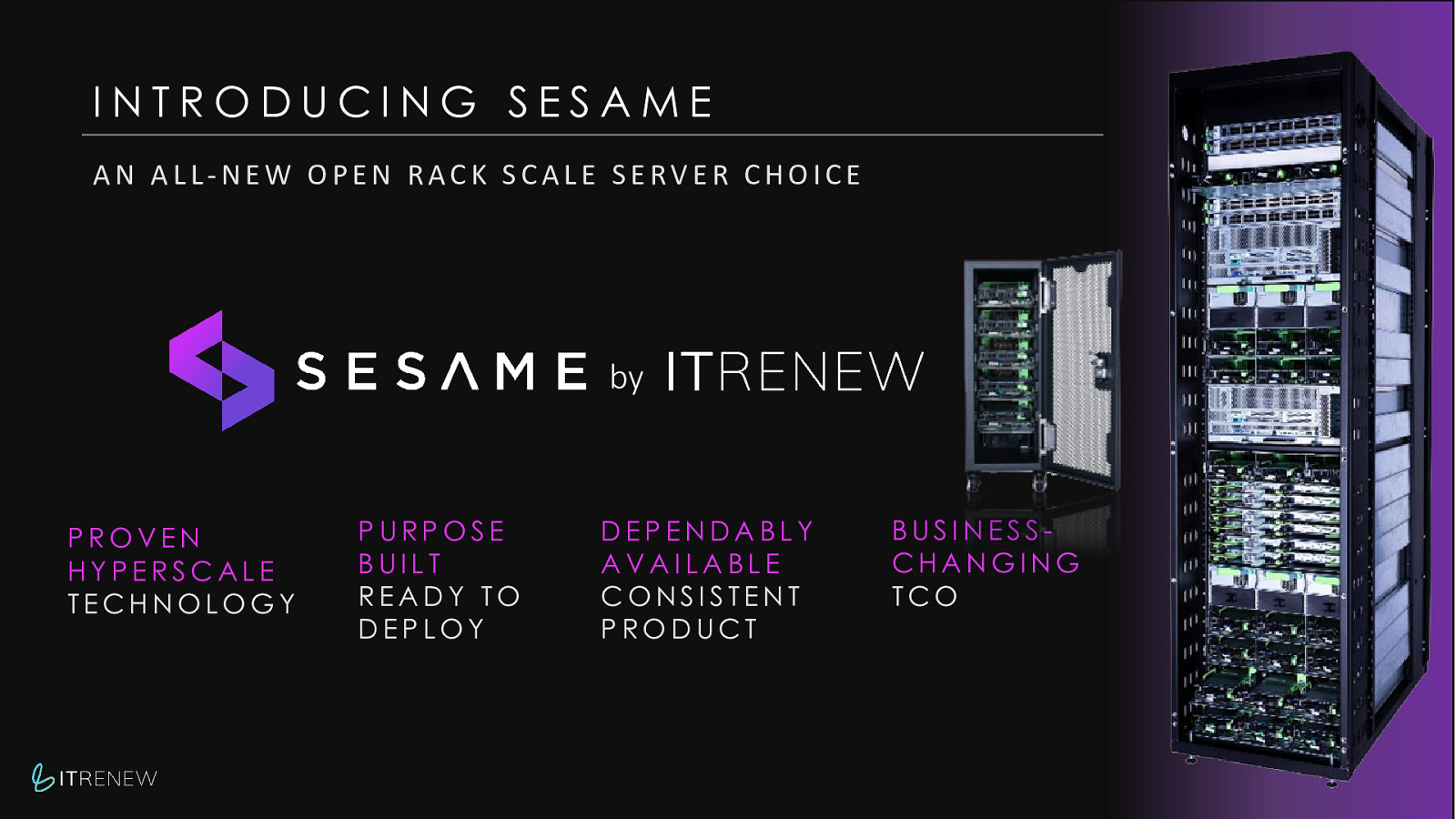

22 INTRODUCING SESAME AN ALL-NEW OPEN RACK SCALE SERVER CHOICE by PROVEN HYPERSCALE TECHNOLOGY PURPOSE BUILT READY TO DEPLOY DEPENDABLY AVAILABLE CONSISTENT PRODUCT BUSINESSCHANGING TCO

THE OPPORTUNITY $50B+ $10B+/yr hyperscale TCO value recovery recent hardware market currently blocked T H E I M P E R AT I V E 24% 24% 52% System TCO savings Net CO2e Savings of global population not online 23

T H AN K YOU E R I K . R I E D E L @ I T R E N E W.C O M I 24

APPENDIX - REFERENCES Note: ITR Proprietary Data and Paid 3rd Party Research excluded from this list

A c a d e m i c Re s e a rc h ( 1 / 3 ) Melek Cumbul Altay, Ülkü Alver Şahin, Burcu Onat, Mert Zoraga, Nüket Sivri (2009): “Recycle of Metals From end-of-life vehicles and relation to Kyoto Protocol”. Anders S. G. Andrea, Otto Andersen (2010): “Life cycle assessments of consumer electronics - are they consistent?”, The International Journal of Life Cycle Assessment, vol. 18, pp. 827 - 836. Deborah Andrews, Beth Whitehead (2019): “Data Centres in 2030: Comparative case studies that illustrate the potential of Design for the Circular Economy as an enabler of Sustainability“ Rabih Bashroush (2018): “A Comprehensive Reasoning Framework for Hardware Refresh in Data Centers”, IEEE Transactions on Sustainable Computing, vol.3, no.4, pp. 209 - 220. David Bol, Sarah Boyd, David Alan Dornfeld (2011): “Application-aware LCA of semiconductors: Life-cycle energy of microprocessors from high-performance 32nm CPU to ultra-low-power 130nm MCU”, Proceedings of the 2011 IEEE International Symposium on Sustainable Systems and Technology, Chicago, IL, 2011, pp. 1-6. Nikhil Krishnan, Sarah Boyd, Ajay Somani, Sebastien Raoux, Daniel Clark, David Dornfeld (2008): “A Hybrid Life Cycle Inventory of Nano-Scale Semiconductor Manufacturing”, Environmental Science & Technology 2008, vol. 42, no.8, pp. 3069-3075. Sarah Boyd, Arpad Horvath, David Dornfeld (2009): “Life-Cycle Energy Demand and Global Warming Potential of Computational Logic”, Environmental Science & Technology 2009, vol. 43, no. 19, pp. 7303-7309. Sarah B. Boyd, Arpad Horvath, and David Dornfeld (2009): Supporting Information for “Life-Cycle Energy Demand and Global Warming Potential of Computational Logic”, Environmental Science & Technology, vol. 43, no. 19, pp. 7303-7309. Sarah Boyd, Arpad Horvath, David Dornfeld (2009): “Life-Cycle Assessment of NAND Flash Memory,”IEEE Transactions on Semiconductor Manufacturing, vol. 24, no. 1, pp. 117-124. Lichuan Chang, Justin Meza, Parthasarathy Ranganathan, Cullen Bash, Amip Shah (2010): “Green server design: beyond operational energy to sustainability”, Proceedings of the 2010 international conference on Power aware computing and systems (HotPower’10). USENIX Association, Berkeley, CA, USA. Kate Craig-Wood, Paul Krause (2013): “Towards the estimation of the energy cost of Internet mediated transactions”. Louis de la Torre (2011): “Natural resources sustainability: Iron ore mining”, Dyna (Medellin, Colombia), vol. 78, pp. 227-234. 26

A c a d e m i c Re s e a rc h ( 2 / 3 ) Liqiu Deng, Callie W. Babbitt, Eric D. Williams (2011): “Economic-balance hybrid LCA extended with uncertainty analysis: case study of a laptop computer”, Journal of Cleaner Production, ISSN 09596526, vol. 19, no. 11, pp. 1198-1206. Mine Ercan, Jens Malmodin, Pernilla Bergmark, Emma Kimfalk, Ellinor Nilsson (2016): “Life Cycle Assessment of a Smartphone”, 4th International Conference on ICT for Sustainability, pp. 124 - 133. Klaus Fichter, Ralph Hintermann (2014): “Beyond Energy - The Quantities of Materials Present in the Equipment of Data Centers”, Journal of Industrial Ecology, vol. 18, no. 6, pp. 846 - 858. Sophia Flucker, Robert Tozer, Beth Whitehead (2018): “Data centre sustainability - beyond energy efficiency”, Building Services Engineering Research & Technology, vol. 39, no. 2, pp. 173 - 182. Christian Hagelüken (2006):” Recycling of Electronic Scrap at Umicore. Precious Metals Refining”, Acta Metallurgica Slovaca, vol. 12, pp. 111-120. Christian Hagelüken (2006): “Improving metal returns and eco-efficiency in electronics recycling - a holistic approach for interface optimisation between pre-processing and integrated metals smelting and refining”, Proceedings of the 2006 IEEE International Symposium on Electronics and the Environment, Scottsdale, AZ, pp. 218-223. Christopher R. Hannemann, Van P. Carey, Amip J. Shah, Chandrakant Patel (2008): “Lifetime exergy consumption of an enterprise server”. Erkko Helminen, Elsa Olivetti, Tom Okrasinski, Larry Marcanti (2017): “Environmental Impact of High Density Interconnect Printed Boards as a Function of Design Parameters”, 2017 IMAPS Nordic Conference on Microelectronics Packaging (NordPac). Norihiro Itsubo, Atsushi Inaba (2003): “Assessment of Environmental Impact of Manufacturing Steel Considering Physical Damage to Human Health”, Materials Transactions, vol. 44, pp. 167-172. Alex K. Jones, Liang Liao, William O. Collinge, Haifeng Xu, Laura A. Schaefer, Amy E. Landis, Melissa M. Bilec (2013): “Green computing: A life cycle perspective”, 2013 International Green Computing Conference Proceedings, Arlington, VA, 2013. Satish V. Joshi, Lawrence T. Drzal, Amar K. Mohanty, Sunil Arora (2004): “Are natural fiber composites environmentally superior to glass fiber reinforced composites?”, Composites Part A: Applied Science and Manufacturing, vol. 35, pp. 371-376. 27

A c a d e m i c Re s e a rc h ( 3 / 3 ) Suthirat Kittipongvises (2017): “Assessment of Environmental Impacts of Limestone Quarrying Operations in Thailand”, Environmental and Climate Technologies, vol. 20, pp. 67 - 83. Ching-Hwa Lee, Chang-Tang Chang, Kuo-Shuh Fan, Tien-Chin Chang (2004): “An overview of recycling and treatment of scrap computers”, Journal of Hazardous Materials , vol. 114, pp. 93 - 100. Atsushi Nakano, Nurul Taufiqu Rochman, Hidekazu Sueyoshi (2005): “LCA of Manufacturing Lead-Free Copper Alloys”, Journal of The Japan Institute of Metals, vol. 71, pp. 885-889. Terry Norgate, Sharif Jahanshahi, William Rankin (2006): “Assessing the environmental Impact of metal production processes”, Journal of Cleaner Production, vol. 15, pp. 838-848. Philip Nuss, Matthew J. Eckelman (2014): “Life Cycle Assessment of Metals: A Scientific Synthesis”. PLOS ONE, vol. 9, no. 7. Masahiro Oguchi, Shinsuke Murakami, Hirofumi Sakanakura, Akiko Kida, Takashi Kameya (2011): “A preliminary categorization of end-of-life electrical and electronic equipment as secondary metal resources”, Waste Management, vol. 31, pp. 2150-2160. Elif Ozkan, Nilay Elginoz, Fatos Germirli Babuna (2018): “Life cycle assessment of a printed circuit board manufacturing plant in Turkey”, Environmental Science and Pollution Research, vol. 25, pp. 26801-26808. Pietro Renzulli, Bruno Notarnicola, Giuseppe Tassielli, Gabriella Arcese, Rosa Di Capua (2016): “Life Cycle Assessment of Steel Produced in an Italian Integrated Steel Mill”, Sustainability, vol. 8, no. 8, pp. 719-733. Tetsuya Suzuki, Jun Takahashi (2005): “LCA of Lightweight Vehicles by Using CFRP for Mass-produced Vehicles”. Christopher L. Weber (2012): “Uncertainty and Variability in Product Carbon Footprinting Case Study of a Server”, Journal of Industrial Ecology, vol. 16, no.2, pp. 203-211. Beth Whitehead, Deborah Andrews, Amip Shah (2015): “The life cycle assessment of a UK data centre”, International Journal of Life Cycle Assessment, vol. 20, pp. 332 - 349. Eric D. Williams, Robert U. Ayres, Miriam Heller (2002): “The 1.7 Kilogram Microchip: Energy and Material Use in the Production of Semiconductor Devices”, Environmental Science & Technology, vol. 36, no. 24, pp. 5504-5510. 28

I n d u st r y S t u d i e s Bureau of International Recycling (2008): “Report on the Environmental Benefits of Recycling”. Carbon Trust (2017): “ICT Guidance built on the GHG Protocol Product Life Cycle Accounting and Reporting Standard”. Deloitte (2015): “Preparatory study for implementing measures of the Ecodesign Directive 2009/125/EC. Task 5 - Environment and Economics“ European Commission (2015): “JRC Science and Policy Report. Environmental Footprint and Material Efficiency Support for product policy - Analysis of material efficiency requirements of enterprise”. Lawrence Berkeley National Laboratory, Berkeley, California (2013): “The Energy Efficiency Potential of Cloud-Based Software: A U.S. Case Study.“ MIT Materials Systems Laboratory (2013): “Exploration of Carbon Footprint of Electrical Products - Guidance document for product attribute to impact algorithm methodology”. Oekoinstitut (2012): “Recycling critical raw materials from waste electronic equipment”. PwC (2016): “Life cycle assessment of CFGF - Continuous Filament Glass Fibre Products“. The Shift Project (2019): “Lean ICT - Towards Digital Sobriety. Report of the working group directed by Hugues Ferreboeuf for the think tank The Shift Project”. U.S. Geological Survey (2004): “Flows of Selected Materials Associated with World Copper Smelting”, by Thomas G. Goonan, Open-File Report 2004-1395. U.S. Geological Survey (2012): “Estimated Water Requirements for the Conventional Flotation of Copper Ores”, by Donald I. Bleiwas, Open-File Report 2012-1089. Worldsteel Association (2014): “Steel in the circular economy - a life cycle perspective”. 29

I n d u st r y W h i te p a p e rs AMD (2015): “Comparative Carbon Footprint Assessment of the Manufacturing and Use Phases of Two Generations of AMD Accelerated Processing Units”. Dell (2010): “Carbon Footprint of a Typical Business Laptop from Dell”, By Markus Stuntz, EMEA Environmental Affaris Manager, May 2010. Dell (2013): “Comparing the Carbon Footprints of 11G and 12G Rack Servers from Dell”, by Markus Stutz, Regulatory Principal Engineer, Environmental Affairs. Fujitsu (2010): “White Paper: Life Cycle Assessment and Product Carbon Footprint. Fujitsu ESPRIMO E9900 Desktop PC”. HP (2017): “Simplified LCA Study on HP’s IT Hardware Recycling Processes”, Life Cycle Assessment report, Public report. Seagate (2016): “Makara Enterprise HDD Product Life Cycle Assessment (LCA) Summary“. Seagate (2016): “Koho Enterprise Solid-State Drive Product Life Cycle Assessment Summary“. 30